Top Benefits of Using 19×7 Non-Rotating Steel Wire Rope in Vertical Hoisting

Top Benefits of Using 19×7 Non-Rotating Steel Wire Rope in Vertical Hoisting: In the high-stakes world of vertical hoisting and critical lifting operations, equipment selection can mean the difference between a successful lift and a dangerous incident. Whether you’re working on a high-rise tower in Riyadh, managing offshore operations in the Arabian Gulf, or lifting equipment on an ARAMCO rig, reliable wire ropes are a must. One standout solution offered by SSTC (Safe and Secure Trading Company) in Saudi Arabia is the 19×7 Non-Rotating Steel Wire Rope.

This specialized wire rope design is a favorite in industries requiring high stability, precision, and anti-spin performance. In this blog, we’ll explore everything you need to know about 19×7 non-rotating wire ropes—from construction and benefits to applications and proper handling.

What is 19×7 Non-Rotating Steel Wire Rope?

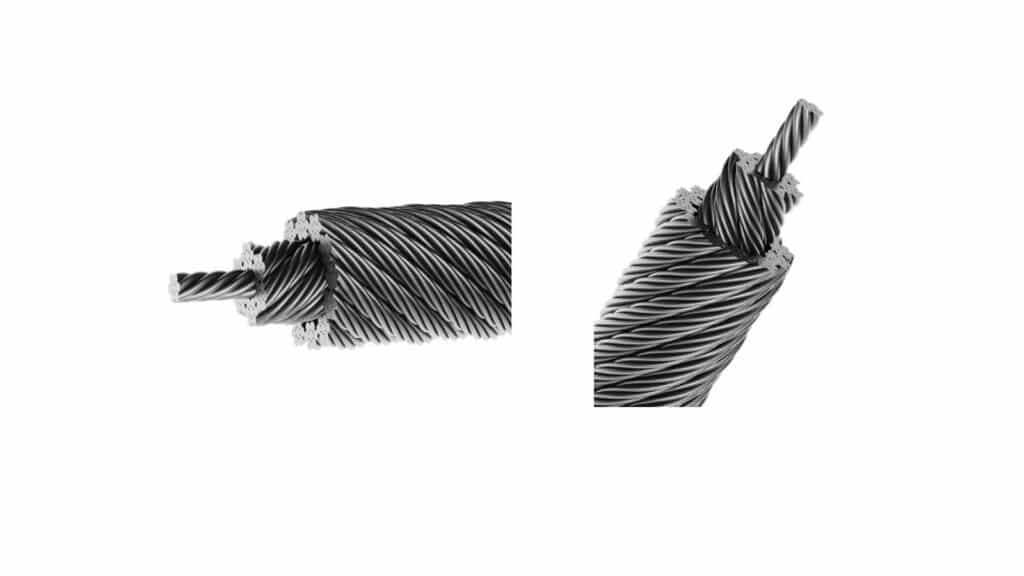

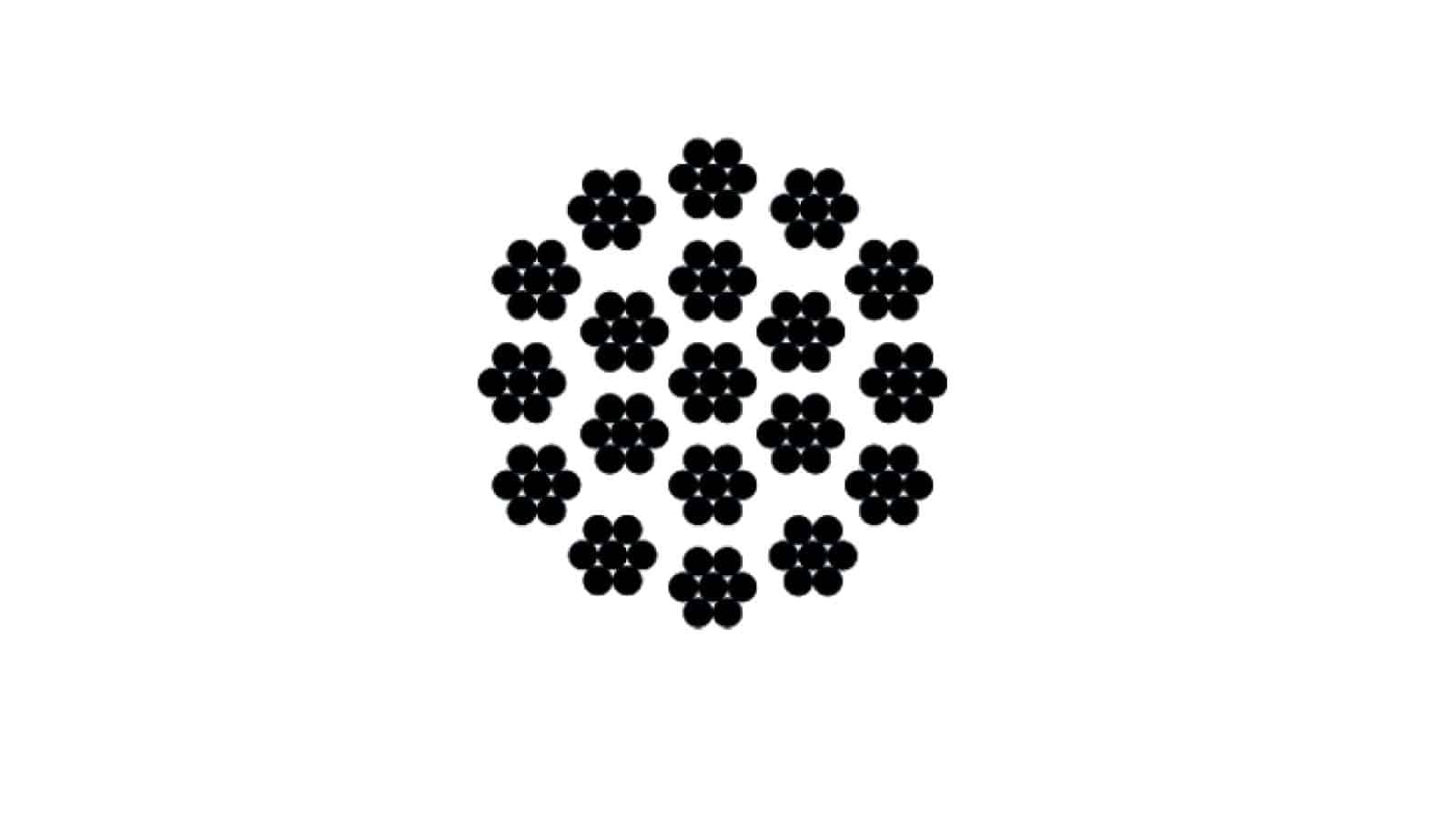

The “19×7” configuration refers to the construction of the rope:

- 19 strands, each made up of 7 wires.

- These are arranged in two layers: an inner layer of 12 strands wound in one direction and an outer layer of 6 strands wound in the opposite direction.

- One center strand completes the construction.

- The opposing lay of the layers cancels out torsional forces, reducing the risk of load rotation during lifting.

This makes it a non-rotating wire rope, especially valuable in vertical hoisting where load spin can cause instability and safety hazards.

Top Benefits of 19×7 Non-Rotating Wire Rope

1. Exceptional Rotation Resistance

One of the main advantages of 19×7 construction is its non-rotating behavior. The rope maintains its position under load, preventing twists and turns that could damage sensitive equipment or cause injury.

This is critical in applications like:

- Tower crane lifts

- Offshore hoisting

- Construction of vertical structures

- Load movement at high elevation

Read Also: 18×7 (6-1)+WSC Wire Rope: A Guide to Rotation-Resistant Steel Rope

2. High Strength-to-Weight Ratio

19×7 wire ropes are made with high-tensile steel wires, delivering a high breaking load with relatively low rope weight. This ensures more lifting capacity with less stress on your crane or hoist.

3. Excellent Flexibility

While slightly stiffer than 6×36 ropes, 19×7 still provides adequate flexibility for use over drums, sheaves, and pulleys—a must for cranes and winches.

4. Resistance to Crushing

The compact structure of 19×7 provides superior resistance to crushing forces. This is particularly important when ropes are wound on multi-layer drums or subjected to intense pressure.

5. Corrosion Protection Options

Available in galvanized or stainless steel, SSTC’s 19×7 ropes are ideal for Saudi Arabia’s harsh coastal and desert climates. Corrosion-resistant versions prolong rope life and minimize maintenance costs.

6. Precision Lifting

Because the rope resists spin and stretch, it allows for precise and stable lifts, especially crucial when handling fragile or high-value cargo.

7. Compliance with Industry Standards

All SSTC-supplied wire ropes meet or exceed industry norms like SASO, ISO, and EN standards, ensuring your operation remains compliant and your workforce stays protected.

Common Applications in Saudi Arabia

The 19×7 non-rotating wire rope is commonly used in:

Construction and High-Rise Development

Used in tower cranes, manlifts, and material hoists across mega-projects in Riyadh, Jeddah, and NEOM.

Oil and Gas Platforms

SSTC supplies 19×7 ropes for drill rigs, platform cranes, and riser lifts used by ARAMCO and offshore contractors.

Port and Maritime Lifting

In ports like King Abdulaziz Port and Jeddah Islamic Port, 19×7 ropes are used for container cranes and marine lifting gear due to their corrosion resistance and spin control.

Industrial Maintenance

Heavy equipment handling in refineries, steel plants, and manufacturing sectors across Dammam, Jubail, and Yanbu.

Mining and Excavation

Ideal for vertical shaft hoisting in phosphate and bauxite mining operations in northern and central Saudi Arabia.

Best Practices for Installation and Use

Handling

- Avoid sharp bends or crushing during uncoiling.

- Use spreader bars or swivels for long rope installations.

Fittings

- SSTC offers pre-fabricated end terminations such as:

- Thimbled eyes

- Spelter sockets

- Swaged fittings

- Turnbuckles and hooks

Inspection Guidelines

Regular inspections are essential for safe lifting:

- Check for broken wires, corrosion, kinks, or flattened strands.

- Replace the rope if defects exceed safety tolerances set by ISO 4309.

Maintenance

- Keep the rope lubricated and clean.

- Store in a dry, covered area, especially in coastal or humid environments.

Why SSTC is the Trusted Supplier in Saudi Arabia

Local Stock, Global Quality

We maintain a ready inventory of 19×7 non-rotating wire ropes for immediate dispatch across the Kingdom.

In-House Testing

Every rope is tested for tensile strength, elongation, and flexibility before delivery.

Full Documentation

SSTC provides:

- Product datasheets

- Material safety data

- Certificates of conformity

- SASO compliance documents

Technical Support

Our team helps with:

- Load calculations

- Custom fittings

- Site inspections

- End-user training

Nationwide Reach

We serve industries in:

- Riyadh

- Jubail

- Dammam

- Jeddah

- NEOM

- Tabuk

- Yanbu

Lifting Responsibly with SSTC

At SSTC, we believe in more than just product delivery—we believe in responsible lifting practices that protect your people, your assets, and your business reputation.

That’s why we:

- Source from certified manufacturers

- Conduct rigorous QA checks

- Promote worker training and education

- Ensure traceability of every wire rope sold

Final Thoughts

The 19×7 non-rotating steel wire rope is an indispensable component in the world of vertical hoisting. With unmatched rotation resistance, high tensile strength, and robust durability, it’s an essential investment for Saudi Arabia’s ambitious infrastructure and industrial goals.

Trust SSTC—where safety, engineering precision, and customer care come together for a stronger, safer Saudi Arabia.

Add comment

You must be logged in to post a comment.